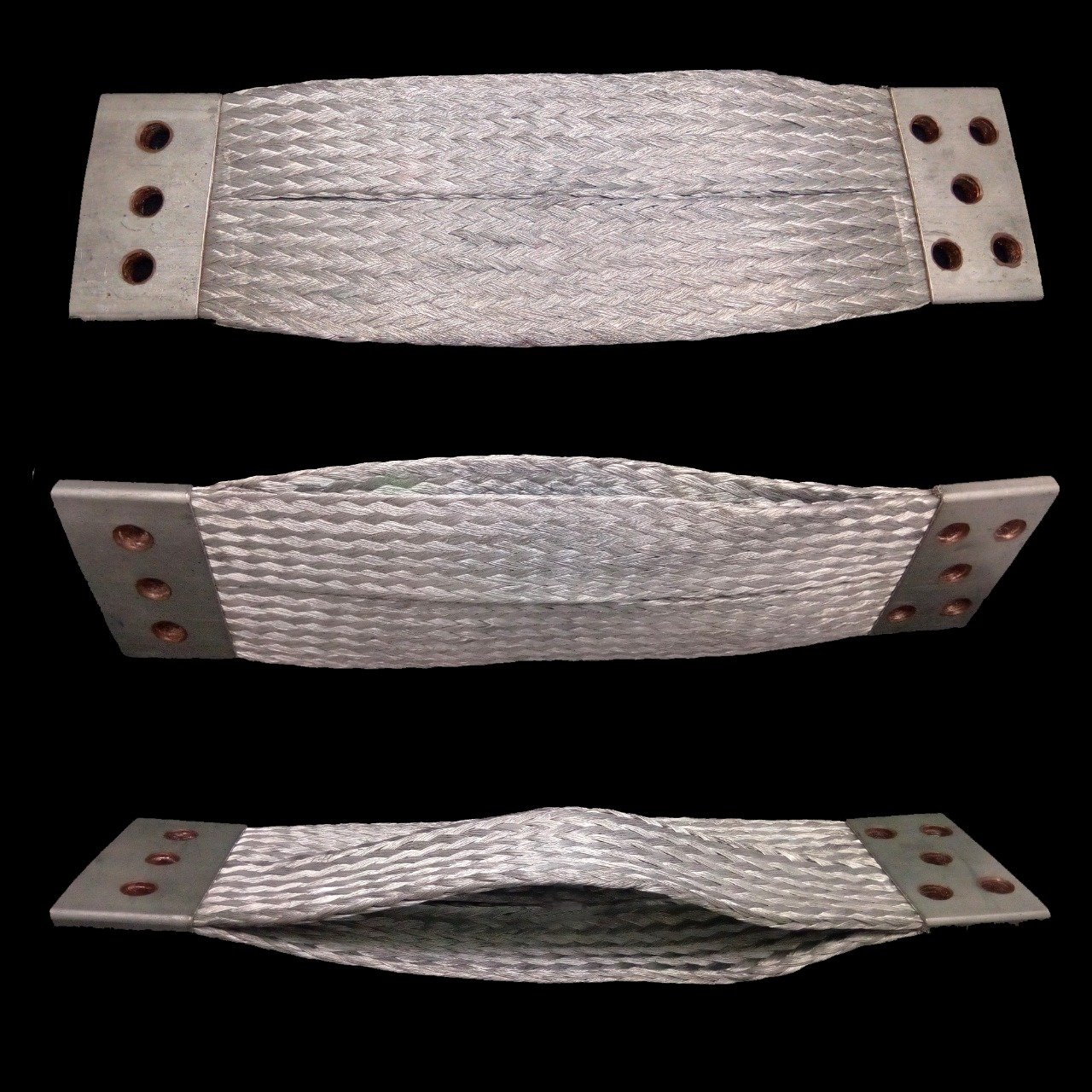

Flexible Braid Bond

Braids made of many copper wires are also sometimes used for flexible electrical connections between large components. The numerous smaller wires comprising the braid are much more resistant to breaking under repeated motion and vibration than is a cable of larger wires. In electrical and electronic cables, braid is a tubular sheath made of braided strands of metal placed around a central cable for shielding against electromagnetic interference. The braid is grounded while the central conductor or conductors carry the signal.

- High conductivity copper

- Wire to Bs - 4109 - C101

- Suitable for Earth Bonding/ also supplied as Standard Drilled & Pre-Cut Bonds.

- Customer specific sizes & types of braid can be manufactured on order.

Generators, turbines and transformers are the prime culprits, causing vibration at key distribution points in electrical power plants, substations and industrial plants. While upkeep and synchronization can reduce the scale of vibration from generators and turbines, the remaining vibration takes its toll over time, as loose connections result in a loss of performance, equipment failure and expansion from heat that dramatically increases the chance of fire. Even with the addition of dampening pads and mounts, vibration still occurs throughout these power distribution networks, loosening lugs and other connectors attached to rigid electrical connectors, like busbars and grounding bars.

Flexible electrical connectors solve high-voltage connectivity problems created by vibration from generators and transformers. When used as the initial connector from vibration-producing equipment to a power distribution network, flexible connectors (or flexible braided jumpers) isolate the main electrical grounding bus work from the cause of vibration.

| Cross Section | Currunt Rating | Dimensions | Drill | |||

|---|---|---|---|---|---|---|

| Area mm2 | AMPS | B mm | D mm | t mm | Holes mm | Type |

| 50 | 250 | 25 | 25 | 4.8 | 11 | J1 |

| 50 | 260 | 30 | 30 | 4.3 | 13 | J1 |

| 50 | 280 | 35 | 35 | 4 | 13 | J1 |

| 75 | 300 | 30 | 30 | 5.5 | 13 | J1 |

| 75 | 330 | 35 | 35 | 5 | 13 | J1 |

| 100 | 360 | 25 | 25 | 8 | 13 | J1 |

| 100 | 360 | 30 | 30 | 7.6 | 13 | J1 |

| 100 | 370 | 40 | 40 | 6.5 | 13 | J1 |

| 100 | 350 | 50 | 50 | 5.8 | 13 | J1 |

| 120 | 420 | 30 | 30 | 8 | 13 | J1 |

| 120 | 420 | 40 | 40 | 7 | 13 | J1 |

| 150 | 440 | 30 | 30 | 8 | 13 | J1 |

| 150 | 480 | 50 | 40 | 7 | 13 | J1 |

| 150 | 480 | 40 | 50 | 6 | 13 | J1 |

| 200 | 500 | 50 | 40 | 8 | 13 | J1 |

| 200 | 600 | 60 | 50 | 7 | 13 | J1 |

| 200 | 625 | 75 | 50 | 6 | 13 | J1 |

| 200 | 630 | 40 | 60 | 4.8 | 13 | J1 |

| 250 | 630 | 50 | 75 | 10.5 | 13 | J1 |

| 250 | 700 | 75 | 40 | 9.5 | 13 | J1 |

| 250 | 725 | 40 | 50 | 8 | 13 | J1 |

| 300 | 750 | 50 | 75 | 11 | 13 | J1 |

| 300 | 780 | 100 | 50 | 10 | 13 | J1 |

| 300 | 790 | 100 | 40 | 8.5 | 13 | J1 |

| 350 | 800 | 40 | 50 | 11.5 | 13 | J1 |

| 400 | 900 | 50 | 60 | 15 | 13 | J1 |

| 400 | 950 | 70 | 75 | 13 | 13 | J1 |

| 400 | 950 | 100 | 100 | 12 | 13 | J1 |

| 400 | 1000 | 100 | 50 | 11 | 13 | J1 |

| 400 | 1000 | 100 | 60 | 10 | 13 | J1 |

| 500 | 1050 | 100 | 75 | 16 | 13 | J1 |

| 500 | 1100 | 100 | 100 | 13.5 | 13 | J1 |

| 500 | 1100 | 100 | 120 | 11.5 | 13 | J6 |

| 500 | 1100 | 100 | 150 | 10.5 | 13 | J1 |

| 500 | 1150 | 100 | 50 | 9.5 | 13 | J1 |

| 600 | 1160 | 120 | 60 | 9 | 13 | J1 |

| 600 | 1180 | 120 | 75 | 17 | 13 | J1 |

| 600 | 1250 | 100 | 100 | 16 | 13 | J1 |

| 600 | 1250 | 110 | 120 | 13 | 13 | J1 |

| 600 | 1270 | 110 | 150 | 11.5 | 13 | J1 |

| 600 | 1300 | 100 | 50 | 10.5 | 13 | J1 |

| 800 | 1350 | 120 | 60 | 10 | 13 | J1 |

| 800 | 1400 | 120 | 75 | 23 | 13 | J6 |

| 800 | 1500 | 100 | 100 | 21 | 13 | J1 |

| 800 | 1500 | 110 | 120 | 20 | 13 | J1 |

| 800 | 1550 | 110 | 150 | 15 | 13 | J1 |

| 800 | 1600 | 110 | 50 | 13 | 13 | J1 |

| 1000 | 1650 | 110 | 60 | 11.5 | 13 | J1 |

| 1000 | 1700 | 120 | 75 | 21.5 | 13 | J1 |

| 1000 | 1800 | 110 | 100 | 16 | 13 | J1 |

| 1000 | 1850 | 110 | 120 | 14.5 | 13 | J1 |

| 1200 | 1950 | 120 | 150 | 13.5 | 13 | J1 |

| 1200 | 2000 | 120 | 75 | 19 | 15 | J1 |

| 1200 | 2150 | 110 | 100 | 16.5 | 15 | J1 |

| 1500 | 2200 | 120 | 120 | 15 | 15 | J1 |

| 1500 | 2300 | 120 | 150 | 23 | 15 | J1 |

| 1500 | 2400 | 110 | 100 | 20 | 15 | J1 |

| 1500 | 2400 | 120 | 120 | 17.65 | 15 | J1 |

| 2000 | 2450 | 120 | 150 | 15 | 15 | J5 |

| 2000 | 2480 | 200 | 200 | 25 | 15 | J1 |

| 2000 | 2520 | 110 | 120 | 22 | 15 | J1 |

| 2400 | 2550 | 120 | 200 | 18 | 18 | J6 |

| 2400 | 2600 | 200 | 120 | 25 | 18 | J7 |

| 3000 | 2850 | 120 | 200 | 20 | 18 | J6 |

| 3000 | 3000 | 200 | 120 | 30 | 18 | J7 |

Notes

- The Above Current Rating IsBased On Ambient Temprature of 30*C And Maximum Temprature Shall Not Excedd 70*C In Free Air

- The above Reffrence Can be Manufactured Is Braided Strips/Rope Standerd Rope Of Copper wire

- Tin Coating Of Copper Wire Results In Excellent Anti Corrosion Rope Of Copper Wire

- All Technical Information Based On Current Rating Is Not Binding The Values Shown Above Are Approximate Values

- The Manufacturer Shall Not Be Held Responsible Under Any Circumstances

- Please Cheq And Adjacent Page For Standerd Drilling Types J